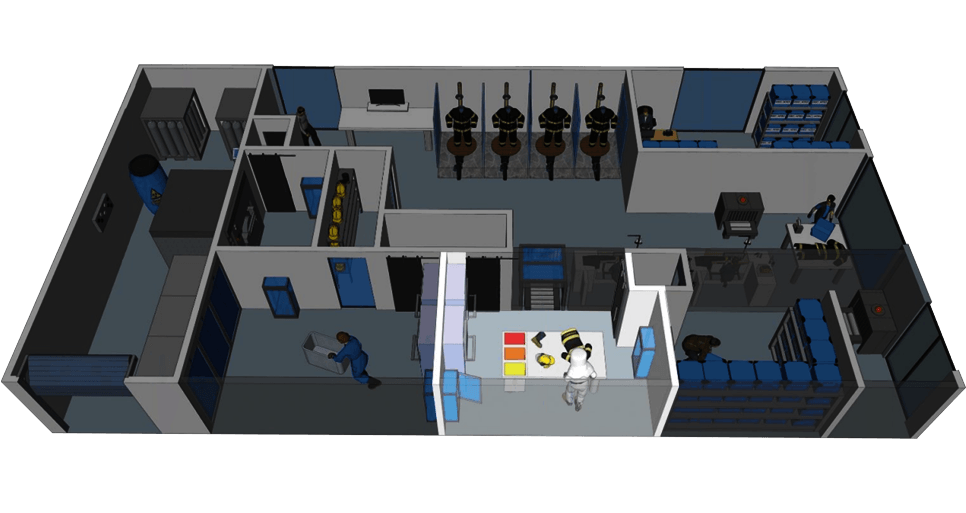

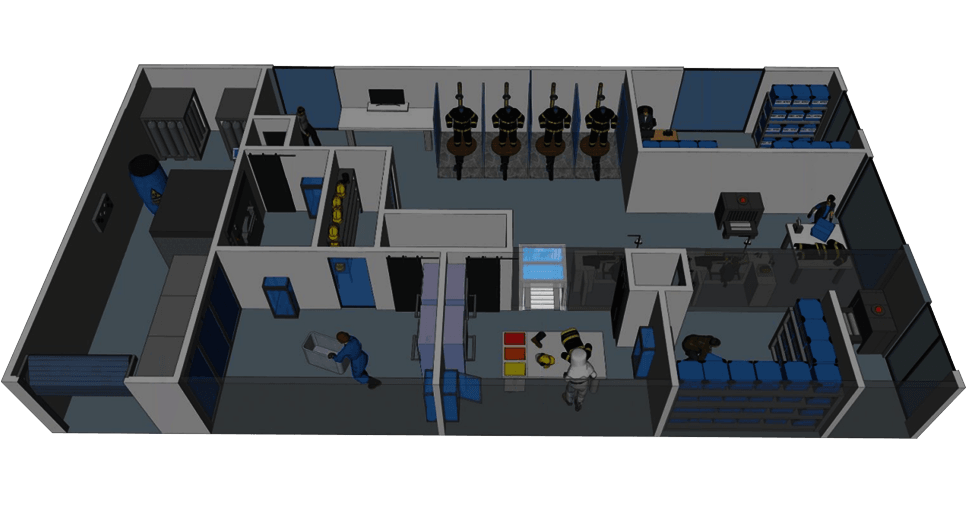

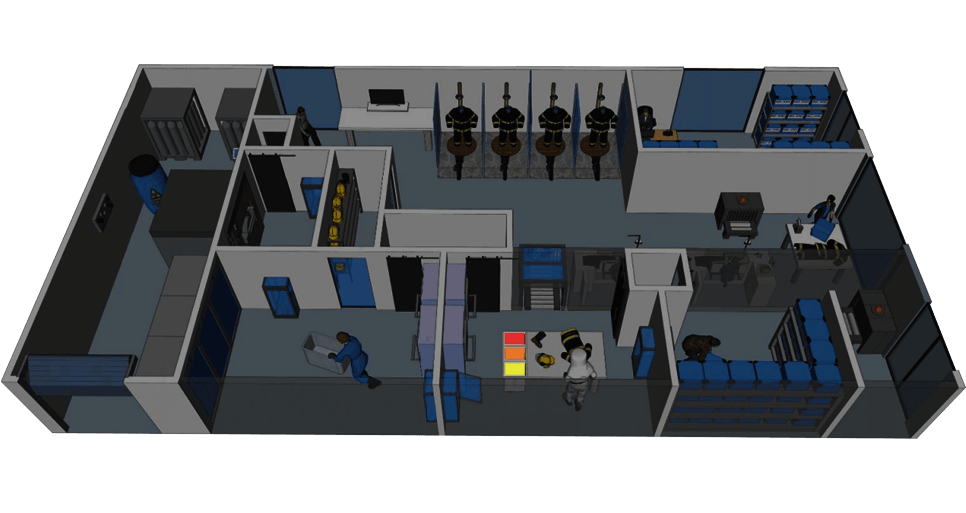

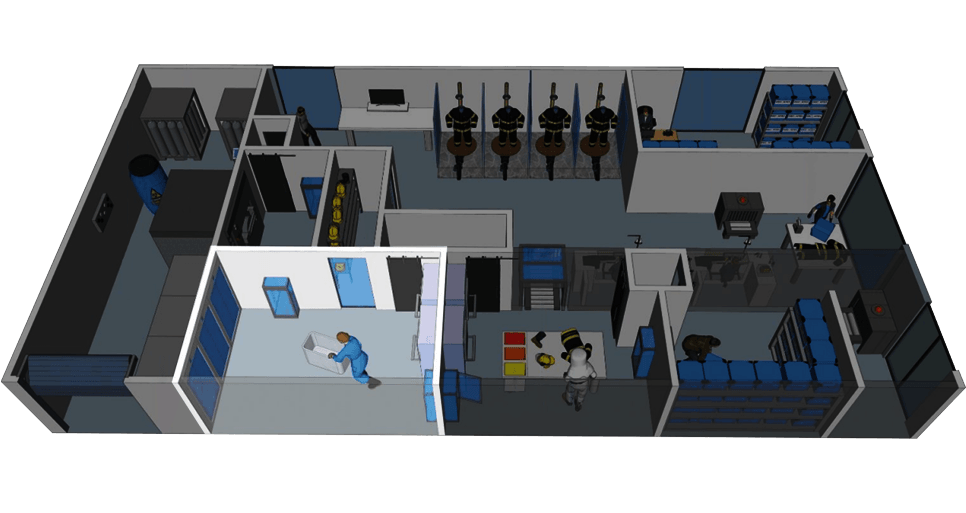

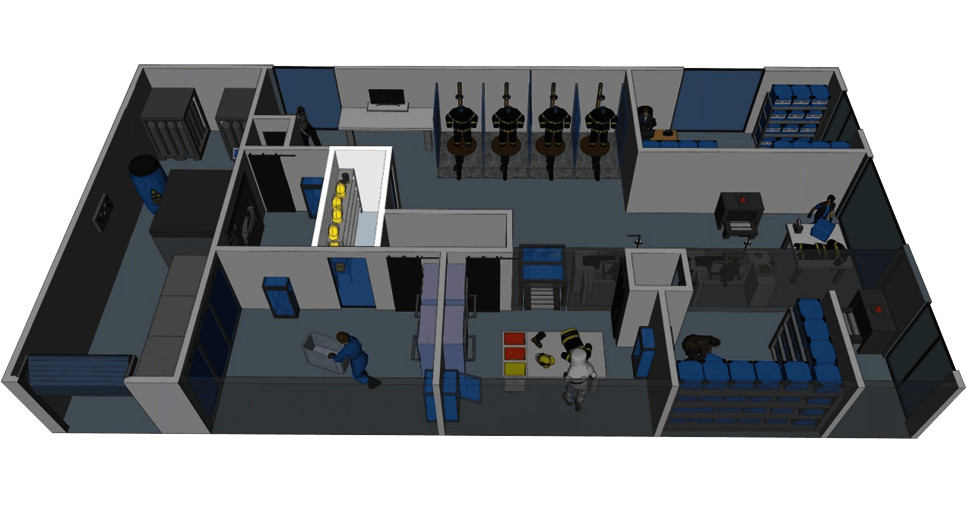

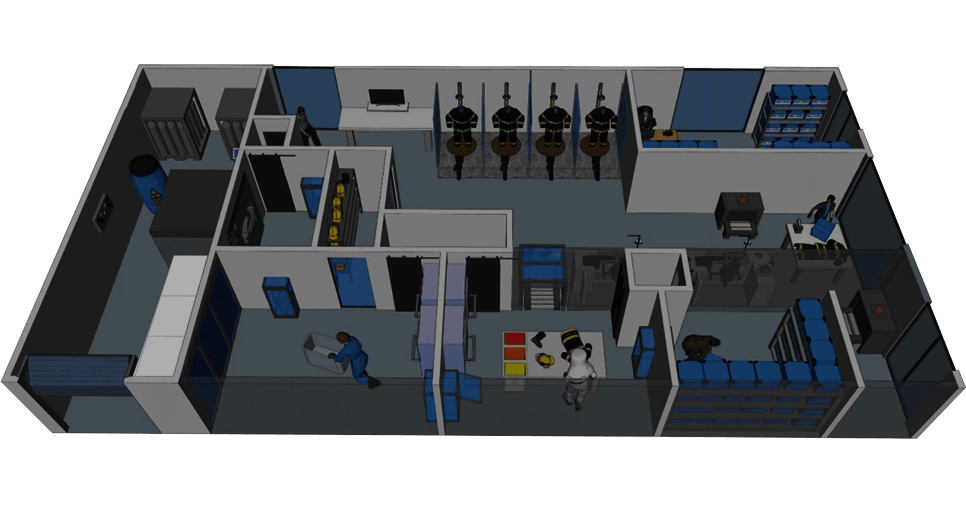

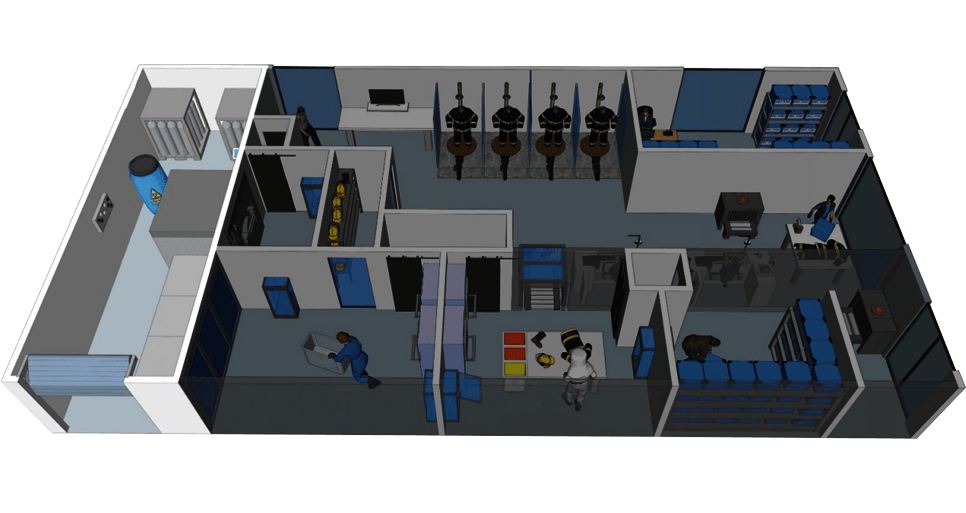

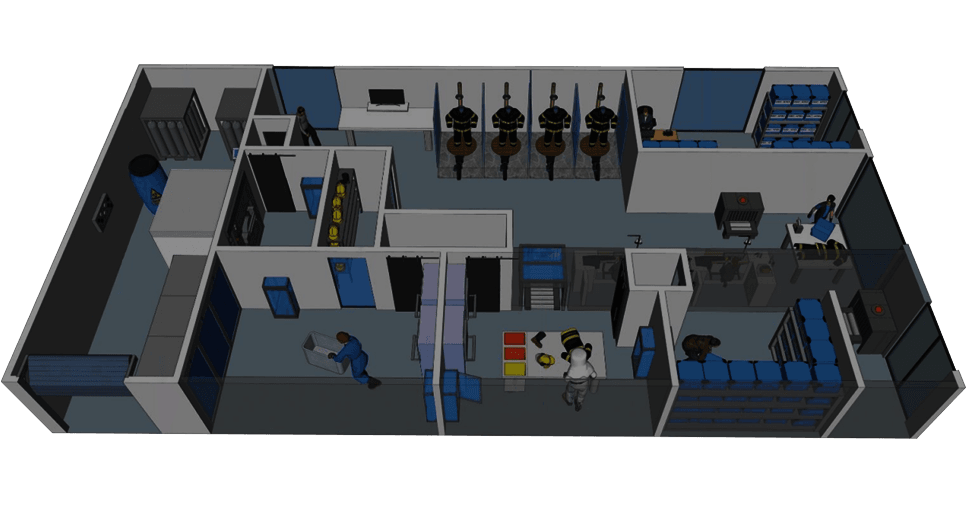

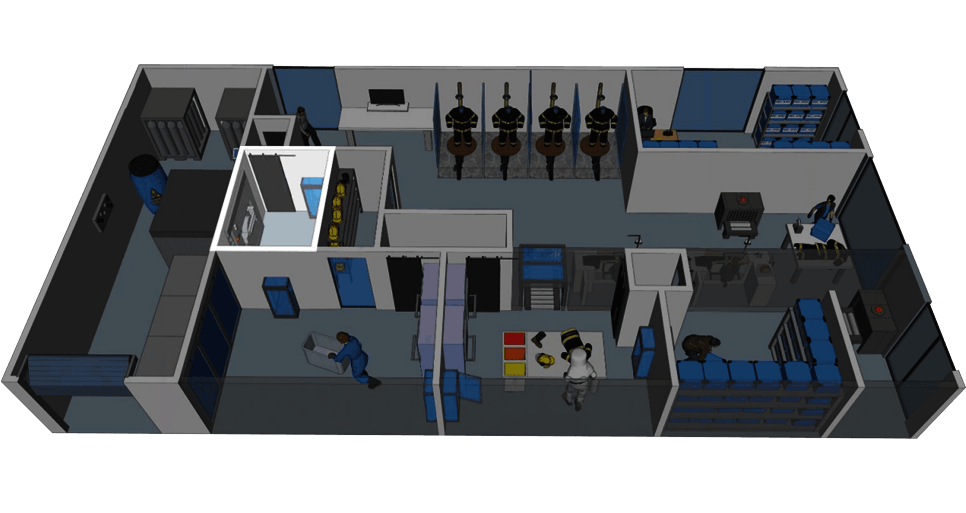

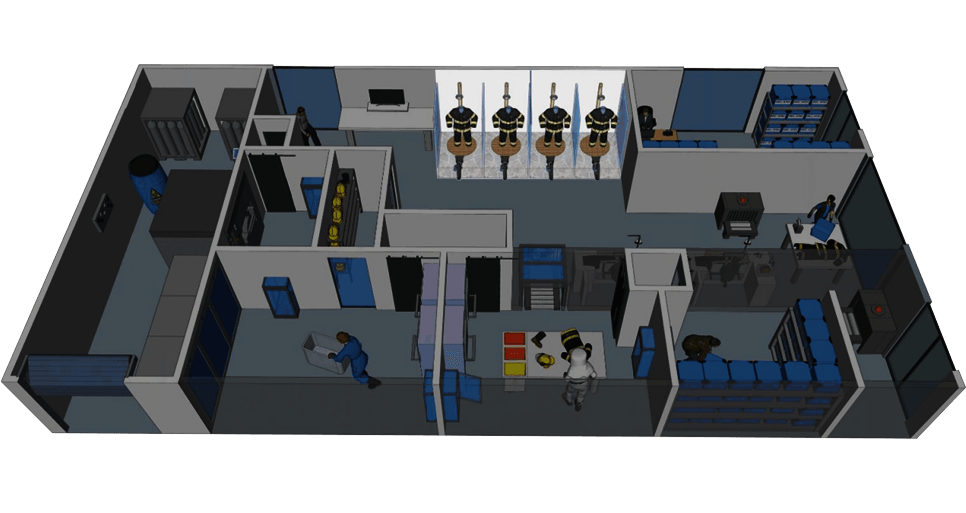

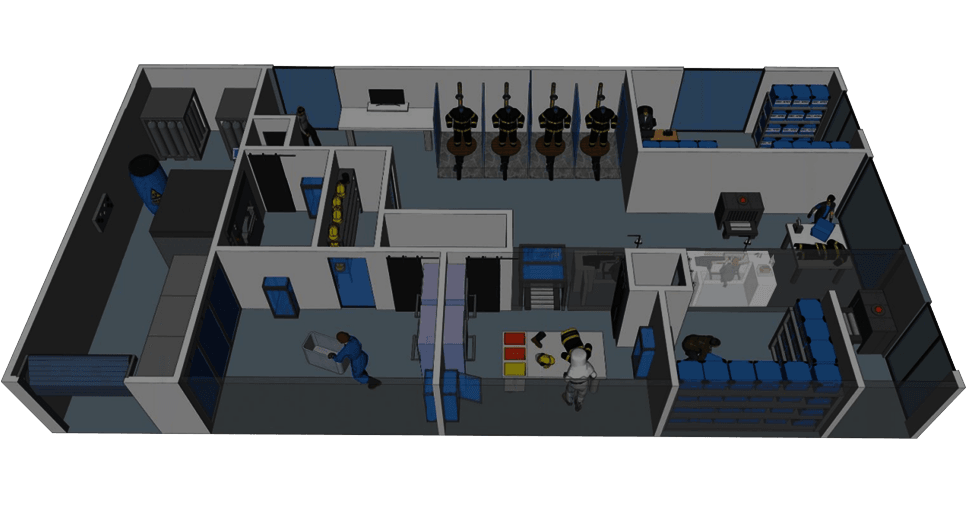

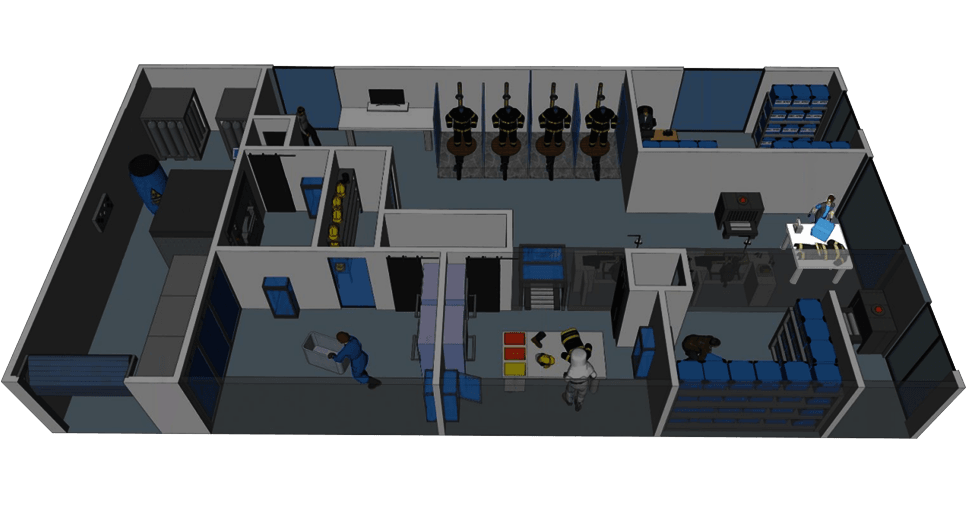

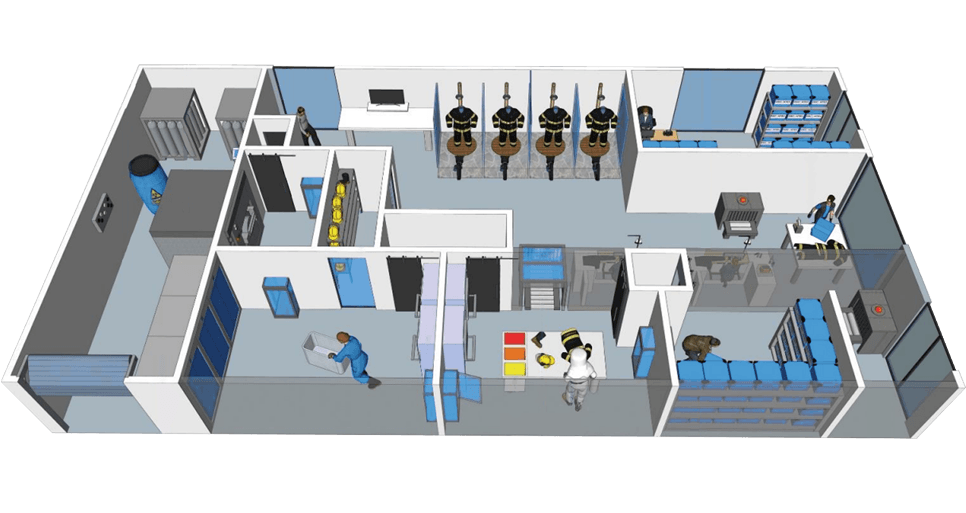

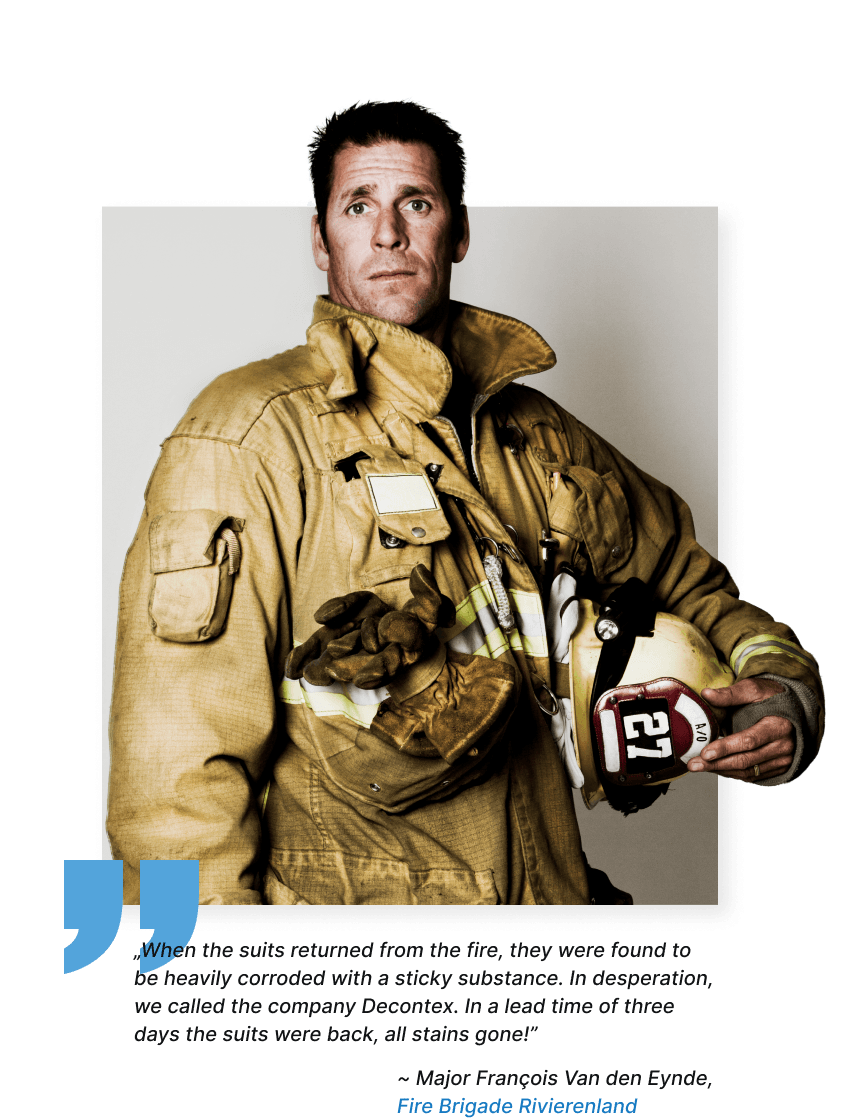

At Decontex, our specialists carefully apply the unique Decontex Technology procedures and develop for you, a tailored maintenance program including cleaning, decontamination, disinfection and repair of your firefighter gear.

We guarantee the removal of all toxic components in firefighter gear, to below legally permitted levels.