DOWNLOAD OUR REPORT

Downloading this freebie is an opportunity you won’t want to miss – it offers a wealth of valuable information.

We return your garment guaranteed free from toxic components, for the highest protection against cancer caused by them.

Introducing the Decontex Guarantee: the promise we make to our customers that we will deliver them fully-decontaminated gear thanks to our Decontex Technology.

Learn more about the Decontex Guarantee:

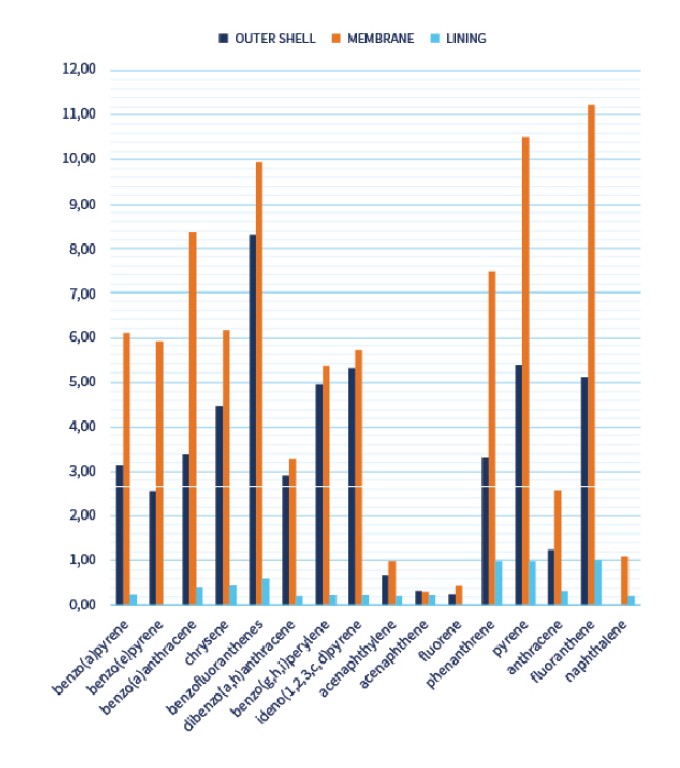

Contaminated fire gear

Study 1: Toxicological profile of contaminated fire gear

When taking samples of fire gear after one smoke intervention, the European notified body for textiles measured an average total PAHs value in the moisture barrier of 143,3 mg/kg, which is almost 15 × higher than the standard.

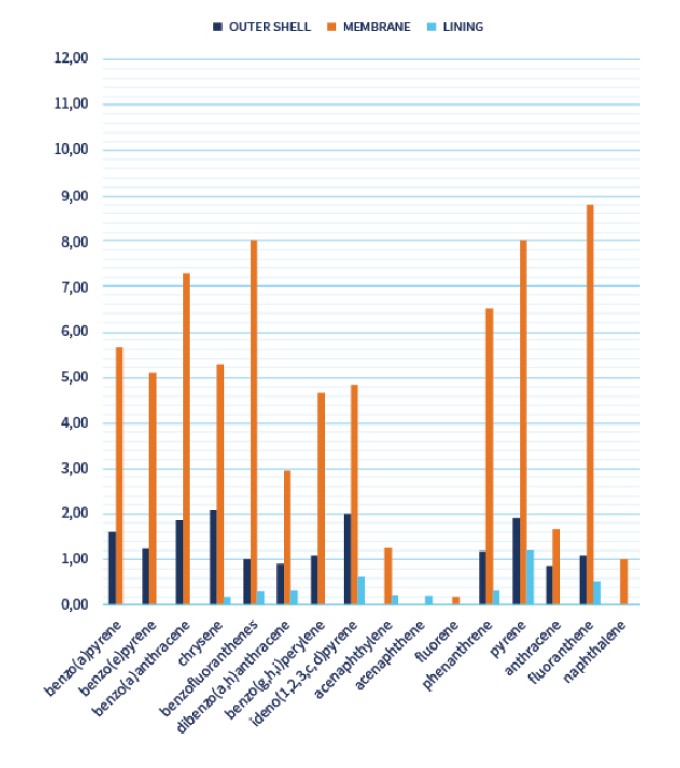

After standard H₂O cleaning

ISO15797

Study 2: Toxicological profile of fire gear after standard ISO cleaning with water and detergents

After cleaning the gear according to a standard ISO cleaning process with water and detergents (18 different programs were tested), a residual amount of 92,28 mg/kg of PAHs was still detected in the gear, which is 9 × higher than the standard. Post standard decontamination, the predominant contamination persists in the moisture barrier (>90%).

After DECO₂FIRE™ Decon

Study 3: Toxicological profile of fire gear after decontamination according to the DECO₂FIRE™ process

After decontamination with Decontex pressurized CO₂, all contaminants are removed of the gear below legally permitted levels (FULL DECONTAMINATION).

Unlike other cleaning and quasi-decontamination processes, Decontex removes all types of contamination, namely: chemical, biological and physical.

We can achieve this without damaging your PPE, which sets us apart from other professional cleaning methods. Damaging the gear can lead to the gradual breakdown of the textile, rendering it non-compliant.

Downloading this freebie is an opportunity you won’t want to miss – it offers a wealth of valuable information.

Completely free of all visible soil and dirt

Free of odours

Fully chemical, biological and physical decontaminated

Free from heavy metals and asbestos

Functional ready for use